People, Process, and Data: Roadblocks and Solutions for AI Implementation in Manufacturing

Posted on: May 2, 2024, by : Tuesday

People, Process, and Data: Roadblocks and Solutions for AI Implementation in Manufacturing

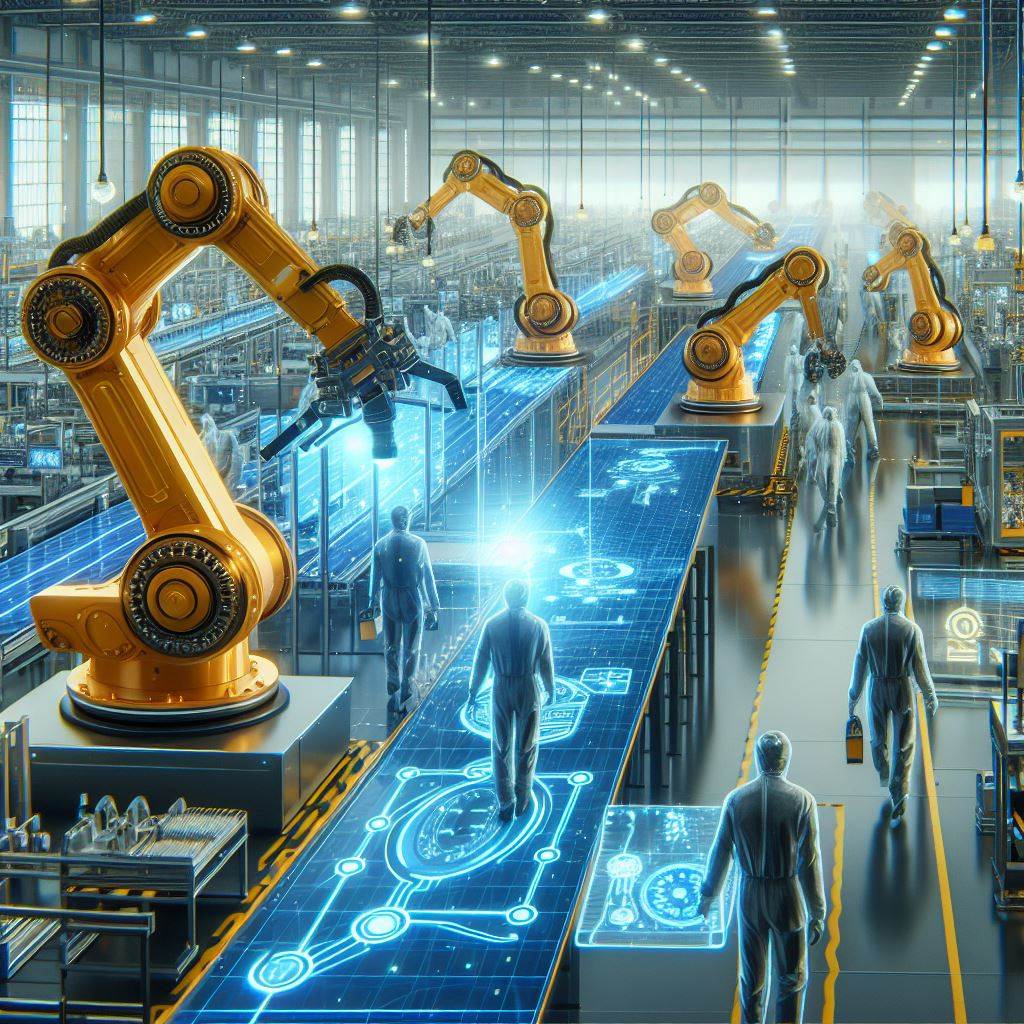

Imagine a factory floor where robots seamlessly collaborate with human workers, machines predict and prevent breakdowns before they occur, and production lines autonomously optimize for maximum efficiency. This is the future that artificial intelligence (AI) promises to bring to the manufacturing industry [1, 4]. However, the path to this future is not without obstacles. Integrating AI into complex manufacturing environments requires navigating a series of challenges.

Hurdles to AI Adoption

One of the significant hurdles to AI adoption is a company’s digital maturity [1]. Organizations with limited digital infrastructure and a less skilled workforce face a steeper climb in implementing AI effectively. Investment in infrastructure upgrades and employee training are crucial for success [1].

Data quality and availability are another critical hurdle. AI systems rely on large volumes of clean, high-quality data to function effectively. Manufacturing environments often struggle with inconsistent data collection practices, making it difficult to ensure data quality meets the demands of AI applications [3].

Cultural resistance to change is another significant barrier. The introduction of AI can be met with skepticism and fear, particularly regarding job displacement [3]. Effective change management, clear communication, and employee education are essential to demonstrate how AI can augment human capabilities and create a more efficient and productive work environment [3].

Additionally, the complexity of AI systems and the need for specialized talent present further obstacles. Implementing AI often requires a workforce with skills in data science, engineering, and AI development, which can be scarce [5]. This talent gap can slow down AI adoption and increase reliance on external vendors, adding to the overall cost [5].

The customization required for AI applications in manufacturing is another significant challenge. Each manufacturing environment has unique needs and processes. Off-the-shelf AI solutions may not be effective, and customizing AI requires significant resources and expertise [4].

Finally, ensuring trust in AI systems is crucial for their successful implementation. Manufacturers need to understand how AI makes decisions to trust its recommendations and actions. Developing AI systems with transparency is essential for their acceptance and effective use in manufacturing environments [1].

Unleashing the Power of AI

Despite these challenges, the potential benefits of AI in manufacturing are undeniable. AI can automate repetitive tasks, improve quality control processes, optimize production scheduling, and drive predictive maintenance strategies [1, 3, 4]. This translates to significant gains in efficiency, reduced downtime, and improved overall equipment effectiveness (OEE).

Advanced AI applications can also analyze vast amounts of data to identify patterns and trends that humans might miss. This can lead to innovative product development, improved process optimization, and the creation of entirely new manufacturing paradigms [4].

As the industry continues to evolve, overcoming the challenges highlighted above will be key to unlocking the full potential of AI in manufacturing. By focusing on digital transformation, data quality initiatives, and a people-centric approach to change management, manufacturers can harness the power of AI to gain a significant competitive advantage.

Reference List

Claude.ai. (2024). https://claude.ai/chat/be9527c2-42bb-464f-a9a0-19fbcad54cb9

MIT Sloan Management Review. (2022, September 27). AI in manufacturing: Start with data, not complex AI systems. https://news.mit.edu/2023/ai-based-estimator-manufacturing-medicine-0503

PwC. (n.d.). Introduction to implementing AI in manufacturing. https://www.pwc.com/gx/en/industries/industrial-manufacturing/publications/introduction-implementing-ai-manufacturing.html

Valiot. (2023, September 12). Overcoming production challenges: Implementing artificial intelligence in manufacturing environments. https://valiot.io/blog/post/optimizing-production-line-efficiency-a-deep-dive-into-valiot-s-ai-driven-solutions?show=8

World Economic Forum. (2024, January 29). How we can unleash the power of AI in manufacturing. https://www.weforum.org/press/2022/12/ai-can-enable-a-new-era-in-manufacturing-sector-says-world-economic-forum-white-paper/

World Economic Forum. (2023, January 23). AI in the manufacturing sector: Barriers to adoption. https://www.weforum.org/agenda/2023/01/ai-manufacturing-sector-barriers-to-adoption/